STAUFF Clamps for the Bulk Solids Industry

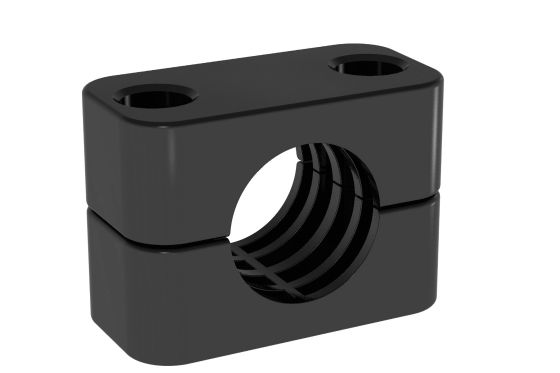

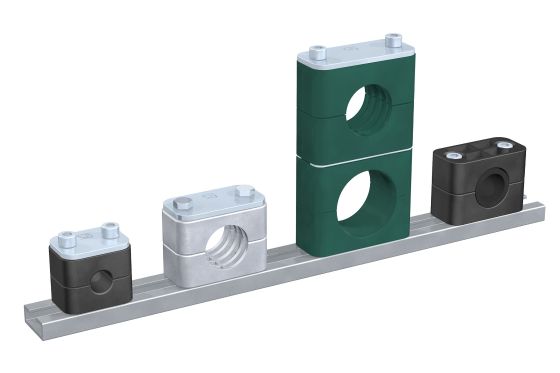

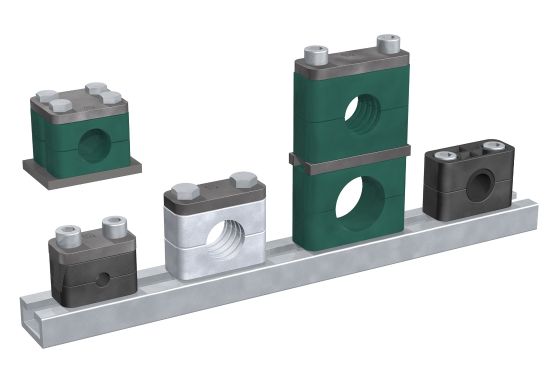

Until now, electrically conductive plastic clamps – whether in the standard version according to DIN 3015 or as a customised variant – were always handled as special parts at STAUFF that were mechanically manufactured individually according to customer requirements. However, this manufacturing process is only economical for small and medium quantities.

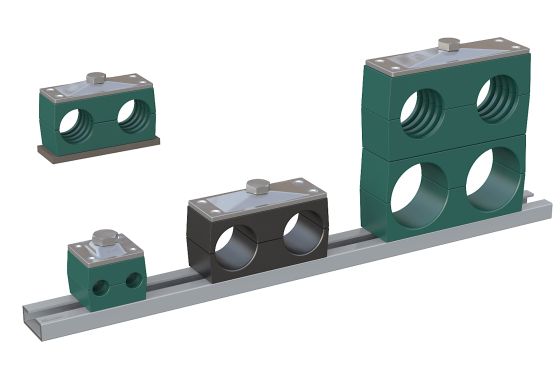

Now these clamps can also be produced in large quantities quickly and at extremely attractive conditions using injection moulding, from a conductive Polypropylene called PP-EC.

By the way: The EC at the end of this material designation is an abbreviation of the English "electrically conductive".

Plastic Clamps: Replacement for Metal Fasteners

When handling bulk solids, for example, the friction of the powdery, granular or lumpy granulates easily generates electrostatic charge. To prevent this from discharging uncontrollably, it must be discharged in a controlled manner. For this reason, pipes, tubes and hoses made of electrically conductive plastics are often used in bulk solids technology, but also in other industries.

These lines are usually fastened with – per se conductive – metallic clamps and brackets, but with the known disadvantages such as the higher weight. In the past, STAUFF has regularly received customer requests for clamps made of electrically conductive materials.

New Material PP-EC is “electrically conductive”

The Polypropylene (PP) used as standard for STAUFF Clamps according to DIN 3015 is, like most plastics, an electrical insulator which increases friction, i.e. it is not conductive.

STAUFF met the customer's requirements by mechanically manufacturing clamps made of conductive Polyethylene (PE) from sheet material in medium and small quantities. For larger runs, injection moulding often makes more sense from an economical point of view. For this purpose, a suitable plastic granulate had to be identified.

Clamps from the PP-EC granulate now used have lower surface resistance (smaller than 104 Ω according to IEC 61340-5-1) than the Polypropylene used as standard for plastic clamps, so they have a conductive effect rather than an insulating one.

Variety of Applications

One of the main areas of application for STAUFF PP-EC clamps is bulk solids technology. Typical bulk solids include building materials such as sand, gravel and cement, raw materials such as ore, coal or clay, but also foodstuffs, for example sugar, salt, coffee or grain.

Apart from the danger posed to the operator by uncontrolled electrostatic discharge, granulates in powdery, granular or lumpy form react differently to electrostatic charging. Some clump together and become unusable for the intended application.

The electrical conductivity of pipes, tubes and hoses and the corresponding fasteners also plays an important role in other industries and applications, such as mining or concrete processing.

The current impetus for this further development of the STAUFF range of clamps for fastening pipes and hoses came from an enquiry from a well-known plant manufacturer for mobile and stationary vacuum systems. Conductivity also plays a major role in this application because sparks can be created and dusts can be ignited by electrostatic charging. In the functional design and manufacture of the systems, steel clamps will be replaced by plastic clamps from now on. STAUFF Clamps made of PP-EC have been extensively tested in practical applications and are now being used in the first configurations.

DIN 3015 Clamps in the STAUFF Online Shop

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog