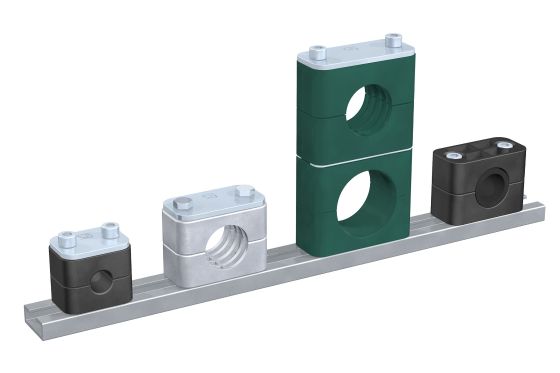

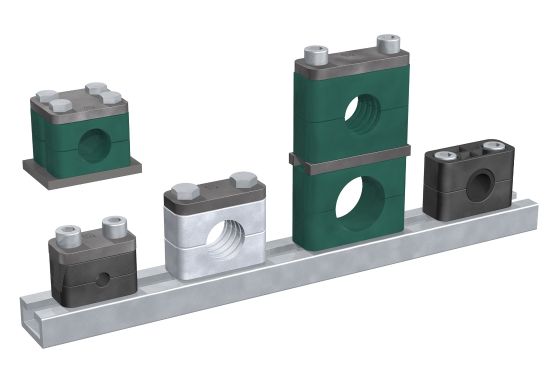

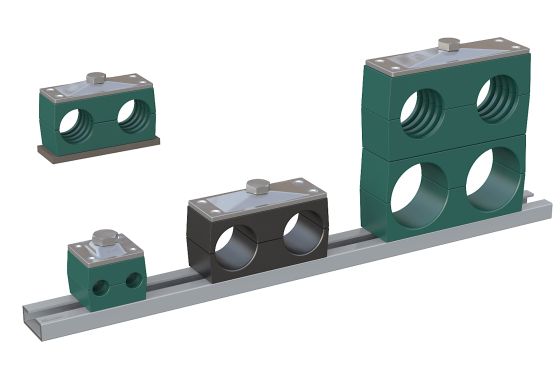

Perhaps you have already asked yourself: Why are Original STAUFF Clamps in the Standard Series, the Heavy Series and the Twin Series according to DIN 3015 actually green? It's not because of the Polypropylene material: PP, as it is referred to in short, has a milky and matt colour as granulate when not coloured. However, the material can be made into almost any colour.

How did STAUFF Clamps become Green?

In the early 1960s, when the invention of the plastic block clamp by STAUFF represented a revolution in hydraulics, green was a colour widely used in industry.

Even into the 1990s, "Reseda Green", the name of the colour corresponding to RAL 6011, was used for lathes and milling machines, for example. Until 1974, exactly this colour, whose name can be traced back to the reseda plant, was even mandatory as a machine paint according to German Industry Standard DIN 1844.

Calming Effect of the Colour Green

But why green of all colours for painting machine tools?

Psychology provides the answer: green has a calming effect and focuses attention. In fact, the DIN 1844 standard was explicitly specified for machine painting for the purpose of accident prevention.

The calming effect of green is also used in the health sector. Patients are supposed to feel less worried by the green clothing of doctors and surgeons.

And the special green shade of classical school chalkboards, which are disappearing more and more from classrooms (at least in Germany), was explicitly recommended by the colour psychologist Heinrich Frieling in the 1960s: The eyes tire less quickly and children can concentrate better.

STAUFF Green – a Sign of Innovation and Quality in Hydraulics

Today's STAUFF green corresponds to the standard colour RAL 6026 and is officially named "Opal Green".

As the corporate colour of the STAUFF Group, this shade of green has become a real trademark in the hydraulics industry over the decades and ensures a high recognition value of original STAUFF products and solutions among customers and users worldwide.

For 60 Years: Preventive Occupational Safety and Environmental Protection with STAUFF Clamps

With clamps made from Polypropylene, STAUFF replaced the metal clamps that had been common until then from the beginning of the 1960s. This was a revolution in hydraulics.

Instead of metal clamps, which constantly loosened under the vibrations of hydraulic pipes and tubes and had to be retightened by entire teams of mechanics, the "clamp squads", plastic clamps now conquered the market.

Reducing vibrations and noise, they are still an important contribution to the leakage safety of hydraulic pipelines and to preventive occupational safety and environmental protection.

The noise made by a vibrating system with hundreds of metal clamps is hard to imagine today. The demands on noise reduction have become even higher over the decades. STAUFF takes this into account with the NRC clamp, for example: The "Noise Reduction Clamp" was specially developed for the particularly noise- and vibration-reducing installation of pipes and tubes.

DIN 3015 Clamps in the STAUFF Online Shop

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog