An important tool - the torque test bench

The torque test bench is an important tool in the development and optimisation of hydraulic tube fittings

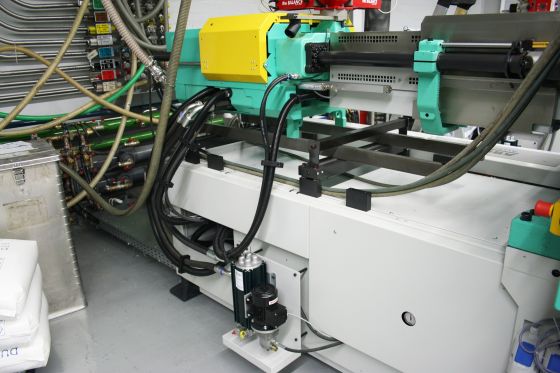

The equipment at the STAUFF Technology Centre includes a torque test bench for determining and documenting the tightening torques of hydraulic tube connectors. The test bench simulates manual installation of a fitting and is an important tool for developing new product ranges or for optimising existing products.

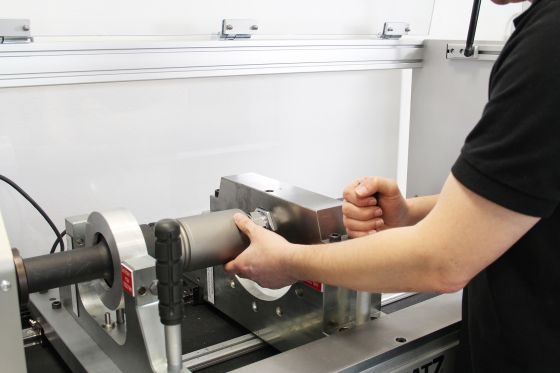

A completely natural sequence of movements for installers and service engineers for hydraulic systems: positioning a tool and tightening a tube connector. The last full turn of the installation tool is prompted by a clear increase in torque, the so-called pressure point

If a high quality product is used and installed correctly, the installer can be certain that the fitting seals reliably.

Typical torque increase

A look at the assembly of cutting ring tube fittings

Relevant factor for development and production

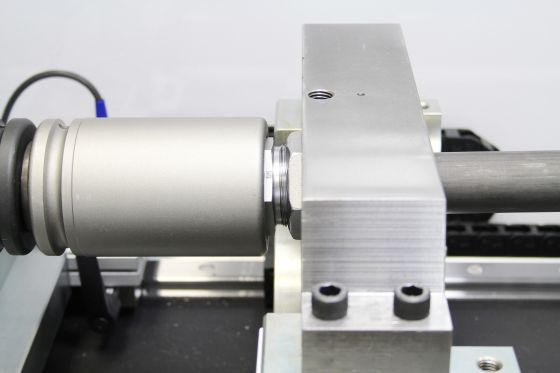

This process is simulated and documented on a test bench at the STAUFF Technology Centre. The test bench recreates exactly what the installer does on the system: it connects the two halves of a tube connector and continuously records the tightening torque that is exerted or required. The test bench can also be used to determine other values such as angle of rotation, pre-tension and thread moment. Torque values up to 3000 Nm can be measured.

A test cycle on this test bench therefore determines the torque progression and increase during installation of tube connectors as well as the required absolute torque at the end of installation. The rest results are of great significance for the (further) development of tube connectors and for quality assurance during production. After all, torque is an essential guiding factor for the development and application of tube connectors.

As low as possible – as high as necessary

The developers follow two principles here. The first: the installation torque has to be low enough to allow comfortable installation of the fitting. Excessive torques cannot be achieved without problems, especially for large sizes. This requires either an extension for the spanner or a second person to support the installer. Both can be difficult or even impossible considering the ever smaller installation spaces of stationary and mobile machines.

The second principle: At the same time, the torque at the end of the installation path has to be high enough to exclude spontaneous release and therefore a risk of leakage under the expected unfavourable conditions (vibrations!). The close link to another test parameter is important here: at the end of installation, a defined pre-tension has to prevent the fitting from releasing. In addition to this, the torque increase at the end of installation has to be high enough for the installer to notice it reliably. This prevents excessive tightening which is often the cause of damage or leaks on tube connectors.

“Window” for optimum tightening torques

These two principles give the developers a range for the optimum tightening torques where the risk of excessive or insufficient tightening can be minimised (for manual installation). The objective is to achieve this torque window.

Naturally, this not only applies to the development of new products or the optimisation of existing ranges, but also to the testing of fittings from current production for quality assurance. The STAUFF torque test bench is used for this task as well. Another area of application is installation with excessive torque.

Finding adjusting options for improvements

The torque test bench allows the STAUFF developers to “fine tune” the optimisation of fittings and to test new processes and materials. STAUFF has already made great progress in this area. The torque progression, for example, was improved by smoothing the cone jacket of cutting rings. Adapting the roughness of cone jacket and cone also supports a reproducible installation process as well as the consistent improvement of the coefficients of friction of zinc/nickel surfaces.

The human factor

The test series on the torque test bench also take into account manual installation of the tube connectors in practical application. So in the end, the human factor is what counts and the results have to be put into context with the findings of human factors and ergonomics: Which torques can actually be achieved manually? By how much does the torque need to be increased at the end of installation in order to be noticeable under all conceivable circumstances? In these cases, the tests on the test bench are “only” the basis for further development work and evaluations.

The bottom line: torque is what counts

For the premium manufacturers of hydraulic tube connectors, torque is the central parameter for the development of new product ranges as well as for quality assurance during production. The previously described examples for the use of the STAUFF torque test bench illustrate this clearly. Beyond this, the test bench is also used for other STAUFF product ranges, for example for recording the screw-in torques of male stud fittings and test couplings or the screw tightening torques for pipe, tube and hose clamps.

This means the torque test bench is not only a practical addition, but rather an important component of the test equipment. In contrast to numerous other test devices, e.g. for pressure impulse and bursting pressure tests, torque testing also includes the targeted optimisation of the ease of use of the tube connectors. The focus here is on the fact that the “right”, comfortable installation process is a crucial factor for the permanent reliability of the connection.

Rate and Comment

Rate posts in the STAUFF blog with just one click or leave feedback and suggestions as a comment – without registration

The editorial team of the STAUFF blog appreciates feedback and suggestions. Accordingly, readers can now not only rate all posts, but also leave comments as guests without prior registration.

And it's that simple:

- Read or view the article.

- Scroll to the bottom of the page.

- Rate the post with just one click.

- Enter a comment.

- Submit your comment as a guest (only your name is required) or create a user account.

- After the comment has been reviewed and approved by the editorial team, it will be published online.

What do you think of this new feature?

Please share your opinion with us now using the rating and comments function!

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog