Test Couplings with Adaption Thread from the STAUFF Test Programme

Measuring couplings with adaption thread from the STAUFF test programme are typically available either with integrated ball valve (type SMK) or cone valve (type SKK) with additional soft seal.

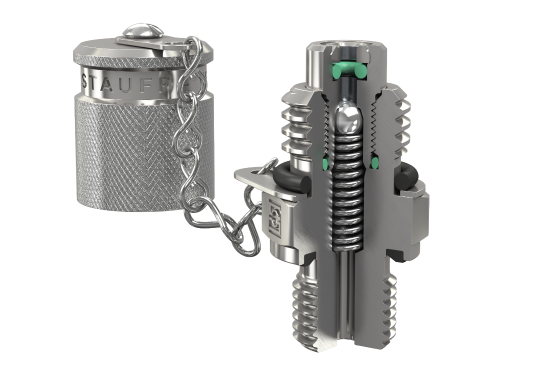

Screw-to-connect test couplings in the STAUFF Test range are typically available with either an integrated ball valve (type SMK) or a poppet valve (type SKK) with an additional soft-sealing element. This blog post serves as a guideline and provides specific information that will help you selecting the most suitable test point design for your particular application.

Test Couplings with Ball Valve

Type SMK test points from STAUFF with an integrated ball valve are usually considered as the standard for regular hydraulic applications using high-viscosity fluids.

For this design, the integrated ball serves as a metal-sealing spring-loaded check valve.

Test Couplings with Poppet Valve

Type SKK test points from STAUFF with an integrated poppet valve and an additional soft-sealing element are the recommended choice for hydraulic applications using low/high-viscosity fluids (e.g. water or cooling lubricants) as well as for high, pulsating pressures or pneumatic applications.

For this design, the integrated poppet serves as a metal-sealing spring-loaded check valve. It is backed up by an o-ring that forms a secondary soft-seal.

Please note: STAUFF can also provide selected versions of type SKK test couplings for natural gas and other gas applications, on request also with corresponding approval certificates (e.g. DVGW or SVGW). Please consult STAUFF for couplings designed for filling applications (with flow in opposite direction).

When a suitable test hose assembly or adaptor is connected to the male adaptation thread of the test coupling, the ball or poppet is pushed back against the integrated spring and the valve opens. This guarantees safe sealing of the connection without any risk of fluid spillage or air inclusion.

Large Selection of Materials

Screw-to-connect test couplings, test hose connectors and most of the accessories in the STAUFF Test range are available in both carbon steel (with superior STAUFF zinc/nickel surface coating for maximum protection and durability) and stainless steel (V2A – 1.4305 / AISI 303 and V4A –1.4571 / AISI 316 Ti) with a variety of sealing materials including NBR (Buna-N®), FKM (Viton®) and EPDM.

Please note: Unless otherwise stated, the external o-ring (located between the coupling body and the metal cap protecting it against self-loosening) is made from NBR (Buna-N®) as standard. And all internal sealings are made from FKM (Viton®) as standard.

If you have specific requirements with regards to the sealing materials, please consult STAUFF.

STAUFF Online Page-Flip Catalogue

Navigate and search content, forward via email, print, and download in PDF format

STAUFF Online Page-Flip Content

Rate and Comment

Rate posts in the STAUFF blog with just one click or leave feedback and suggestions as a comment – without registration

The editorial team of the STAUFF blog appreciates feedback and suggestions. Accordingly, readers can now not only rate all posts, but also leave comments as guests without prior registration.

And it's that simple:

- Read or view the article.

- Scroll to the bottom of the page.

- Rate the post with just one click.

- Enter a comment.

- Submit your comment as a guest (only your name is required) or create a user account.

- After the comment has been reviewed and approved by the editorial team, it will be published online.

What do you think of this new feature?

Please share your opinion with us now using the rating and comments function!

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog