Why the weakest link counts

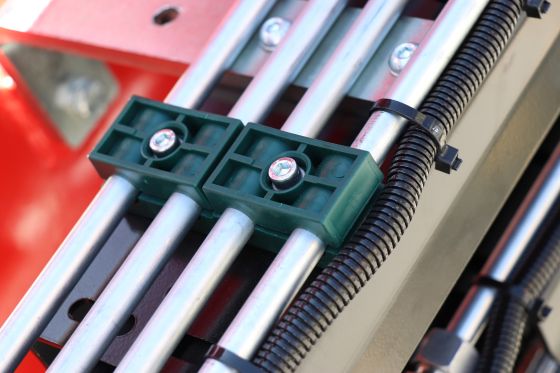

"A chain is only as strong as its weakest link." This sentence can be applied very well to pipe clamps as they are manufactured in accordance with DIN 3015. In practice, it often turns out that it is not the clamp itself but the bolts used that are the critical factor.

Choosing the right bolts is therefore not just a technical side issue, but essential for the safety, functionality and durability of the connection. In this article, we show what is important when it comes to bolt strength, how to recognise high-quality bolts and what risks inferior products can harbour.

Why bolt strength is crucial

Pipe clamps are often exposed to high mechanical loads - whether due to vibrations, temperature changes or pressure surges in the system. If the bolts used cannot permanently withstand these forces, there is a risk of losing the defined holding force. In the worst case scenario, this can lead to breakages, leaks or system damage.

The following applies to DIN 3015 pipe clamps in particular: the bolt is often the weakest link. It is therefore crucial to choose bolts with sufficient strength - in the truest sense of the word.

What does the strength class of a bolt mean?

The strength class of a mild steel bolt - for example 8.8 - is a short form that summarises two properties of the material:

The first digit (here: 8) indicates the tensile strength of the bolt material, multiplied by 100, so an 8 corresponds to 800 N/mm².

The second digit (also 8) stands for the ratio between yield strength and tensile strength, in this case 80 %. This results in a yield strength of 640 N/mm².

The tensile strength describes the maximum stress that a material can withstand before it breaks. The yield strength describes the point up to which the material is completely deformed after being unloaded - i.e. no permanent deformation occurs.

This classification is regulated in the DIN EN ISO 898-1 standard.

A comparison of the common strength classes

Bolts are available on the market in different strength classes - with some significant differences:

Strength class | Tensile strength (N/mm²) | Yield strength (%) | Application |

4.8 | 400 | 320 (80 %) | Lightweight connections, not suitable for pipe clamps |

6.8 | 600 | 480 (80 %) | Medium loads, not standard-compliant for DIN 3015 |

8.8 | 800 | 640 (80 %) | Standard for pipe clamps according to DIN 3015 |

10.9 | 1000 | 900 (90 %) | Higher requirements, e.g. mechanical engineering, power stations |

12.9 | 1200 | 1080 (90 %) | Highly stressed safety-critical connections |

Stainless steel bolts also have their own classifications according to ISO 3506, e.g. A2-70, where A2 stands for the steel grade and 70 for the strength (700 N/mm²). These figures are not directly comparable with the values of steel bolts, but also indicate the load-bearing capacity.

Risks of inferior or counterfeit bolts

There are also bolts on the market that pretend to have a higher strength class than is actually the case. These counterfeits are often not recognisable to the naked eye, but can have fatal consequences in an emergency.

Inferior bolts:

Already deform or even tear off under low mechanical loads,

lose their holding function,

jeopardise the safety of systems and personnel.

The supposedly cheaper bolt can quickly lead to expensive repairs, downtime or even personal injury.

How to recognise high-quality bolts

At STAUFF, we consistently focus on tested quality. Our original bolts offer:

Labelling directly on the bolt head (e.g. 8.8 for AS/IS bolts)

Unique order designations, e.g. AS-M16x130-DIN933-8.8-W3

Traceability via labels and sales receipts

Corrosion-resistant zinc/nickel surface for a long service life

As a general rule, bolts should always come from reputable and documented sources. Our recommendation: Pipe clamps are best purchased as complete sets with matching bolts. This ensures that all components are optimally matched to each other - and that the quality complies with standards.

Our recommendation from practical experience

At STAUFF, we supply our pipe clamps as complete sets including standard-compliant bolts on request. This ensures safety - both during installation and operation. For particularly demanding applications - such as in power station construction or for systems subject to high dynamic loads - we also offer bolts in higher strength classes such as 10.9 or 12.9.

In this way, we guarantee that all components used are perfectly matched - for maximum safety and service life.

Small but crucial

Bolts are inconspicuous - but crucial. Particularly with pipe clamps in accordance with DIN 3015, the correct strength class of the bolts is crucial for the function and safety of the entire connection.

Anyone who skimps or chooses carelessly here risks failures, damage or even accidents. With tested bolts, as supplied by STAUFF as standard in complete sets, you are on the safe side - without any compromises.

FAQs

What does 8.8 mean for mild steel bolts?

Why are 4.8 or 6.8 bolts not sufficient for pipe clamps according to DIN 3015?

These bolts have a significantly lower tensile strength and break more quickly under load - they do not comply with the standard.

Can I also procure bolts myself?

Possible, but risky. Counterfeit or incorrectly labelled bolts are not uncommon. We recommend complete sets.

How can I recognise high-quality bolts?

By the visible strength labelling and the complete documentation (e.g. labels, delivery note).

What do designations such as A2-70 mean?

These are stainless steel bolts. A2 stands for the material type, 70 for the tensile strength in N/mm² x10.

What strength classes does STAUFF offer for pipe clamps in accordance with DIN 3015?

8.8 as standard, optionally also 10.9 and 12.9 for safety-critical applications.

Newsletter registration

Subscribe to the newsletter now and never miss a new article again!