Increase safety, prevent downtime

A hydraulic hose that bursts or tears off under high pressure can have serious consequences: unplanned machine and production downtime, high repair costs and, above all, an enormous safety risk for people and the environment. Leaking operating media under high pressure and uncontrolled hose ends whipping around pose a serious risk.

Our STAUFF hose connectors make an important contribution to the safety of hydraulic systems. Find out here how our innovative solutions help to minimise the risk of hose ruptures and maximise the reliability of your hydraulic applications.

Our two-part fitting system, consisting of a hose nipple and a matching press fitting, has been specially developed for the diverse requirements of hydraulics. Our aim is to offer our customers not only maximum functionality, but also cost savings and environmental benefits through innovative solutions.

Why is Ecovos actually called Ecovos?

The name Ecovos is our registered word mark and combines two key aspects of our hose connectors:

Eco: as a reference to Economical stands for economy and efficiency. This refers to the universal nipple profile, which is compatible with a wide range of different hose types. This means that customer stocks of different individual components in the hose workshop or service vehicle can be reduced by up to 45 per cent.

Vos: For the origin from the original production at Voswinkel in Meinerzhagen. With the takeover of Voswinkel in 2015, hydraulic hose fittings became an integral part of the STAUFF product range - optimised for maximum flexibility, durability and performance. We have been distributing the products exclusively under the STAUFF brand since 2018.

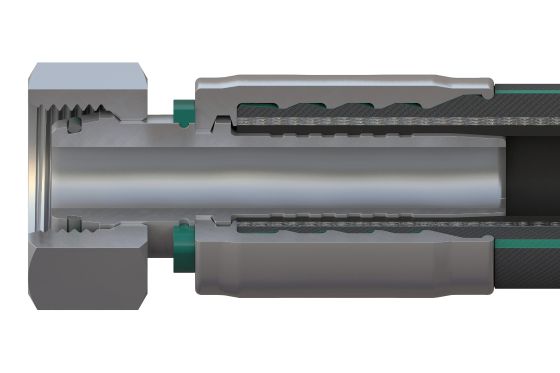

Technical design and safety

STAUFF zinc/nickel surface with special additives in the sealant

Advantages:

- Increased corrosion resistance and protection against premature wear

- No lubrication of threads or cones required during assembly

Benefit:

- Increased durability and safety

- High-quality appearance

- Process cost reduction through simplification of assembly processes and savings on lubricants

- Reduced potential for errors during assembly

- No apparent leaks due to residual oil sweating out during operation

- Environmental protection due to lubricant savings and less lubricating oil leakage during operation

O-ring up to 15%~20% further upstream

Advantages:

- Secure fit even in worn mounting cone

Benefit:

- Increased assembly safety

Separate green backing ring outside the frame groove

Advantages:

- Ensures ideal contact/positioning of the crimped socket in the socket groove of the hose nipple

Benefit:

- Reliable pressing process

Universal profile of the hose nipple

Advantages:

- Maximum compatibility with different hose types

Benefit:

- Process cost reduction through the use of identical parts and resulting inventory optimisation

Tapered mounting area of the press mount

Advantages:

- Greater form fit during pressing

Benefit:

- Avoidance of torsion of the press fit

Hose stop in the press fitting

Advantages:

- Safe hose positioning, simple positioning

Benefit:

- Process reliability during pressing

Significantly longer nipple tail

Advantages:

- Larger contact surface for the hose

Benefit:

- Higher surface pressure, higher tear-out resistance, higher torsion resistance, higher leakage resistance

Mandrel measuring system available

Advantages:

- Ensuring the optimum pressing dimension setting

Benefit:

- Higher surface pressure, higher tear-out resistance, higher torsion resistance, higher leakage resistance

Conical outlet of the hose nipple

Advantages:

- Simplified attachment or sliding of the hose onto the hose nipple

Benefit:

- Increased assembly safety

Tooth design of the press fittings, optimised for the respective hose type

Benefit:

- Increased longevity and safety

Support collar at the outlet of the press fittings

Advantages:

- Sealing zone against external moisture ingress

Benefit:

- Longevity of the connection

Fixing groove for retrofittable mobile pull-out protection on the hose nipple

Advantages:

- Use as a pull-out-proof interlock fitting for hose types 4SH or R15

Benefit:

- Process cost reduction through the use of identical parts and the resulting stock optimisation

The Ecovos series is characterised by the innovative design of the hose nipple - as it is significantly longer than comparable products. This calming section specifically minimises stress in the integration area (sealing profile zone). This integration profile leads to several decisive advantages:

Increased safety: even in critical applications such as travelling drives and lift and punch cylinders, the extended bonding area ensures a stable and secure connection. This effectively prevents leaks and the hose from slipping out.

Improved torsion protection: The increased protection against twisting (torsion) ensures that the connection functions reliably even under demanding operating conditions.

Fewer failures: The design advantages contribute to a lower risk of failure of the pre-assembled hose lines in use and, in turn, increase cost-effectiveness.

Our Dornvos test mandrel system helps the assembler to ensure that the connection is correct and thus makes a decisive contribution to the operation of safe hose assemblies.

Our fittings are made of steel with a STAUFF zinc/nickel surface that offers high resistance to red rust even after crimping. As an option, we also offer Ecovos in stainless steel - in this case known as Evocos VA.

Universal compatibility and bearing optimisation

Another key aspect of our Ecovos series is the versatile hose nipple profile. This universal profile enables the use of a wide range of common hydraulic hose types, including

Braided hoses: 1SN, 2SN (EN 853)

Compact braided sleeving: 1SC, 2SC (EN 857), 1SNK, 2SNK,

Textile hoses: 2TE, 3TE (EN 854)

Multi-spiral hoses: 4SP, 4SH (EN 856 with wire spiral inserts)

Isobaric hose types

Depending on the type of hose used and the crimped fitting, it may be necessary to peel the hose beforehand - details can be found in our catalogue and in the crimping dimension tables.

Thanks to the universal profile, we reduce the stocking of different individual components by up to 45 per cent by using identical parts. This leads to more efficient warehousing and optimised logistics processes.

Simple assembly and environmental benefits

Our well thought-out design of the Ecovos hose fittings also offers clear advantages during assembly.

No lubrication of the threads: Thanks to special additives in the sealant of the STAUFF zinc/nickel surface, there is no need to lubricate the threads or cones during assembly. This leads to

Cost reductions through savings on lubricants

Reduced potential for errors during installation

Avoidance of false leaks due to residual oil during operation

Environmental benefits thanks to less lubricating oil leakage

Ease of installation: The slightly conical outlet of the hose nipple ensures less force is required when pushing on the hose, reducing the amount of work required and at the same time minimising the strain on the hose, especially when bending.

These features not only make our fittings user-friendly, but also contribute to sustainable and economical use.

Areas of use and industry applications

Our Ecovos hose connectors are used in numerous areas of application where maximum safety and reliability are required. Typical areas of application include

Industrial hydraulics: For stationary use in manufacturing plants and production systems.

Mobile hydraulics: In small construction machinery, agricultural and forestry machinery as well as utility and municipal vehicles, where manoeuvrability and robustness are crucial.

Critical applications: Especially where maximum safety is required - such as in travelling drives or lift and punch cylinders.

Our solutions help to ensure that the hydraulic systems in all these areas function optimally, minimise failures and maximise efficiency.

FAQs

What distinguishes Ecovos hose connectors from other products?

In general, torsion should be avoided when using hose lines. If this does occur, the design of our hose fitting will help you. Our Ecovos series has an extended hose nipple, which ensures increased safety, better torsion protection and a lower failure rate. In addition, the universal profile offers maximum compatibility with common hydraulic hose types.

Which hose types are compatible with Ecovos?

The fittings are compatible with various hose types such as braided hoses (1SN, 2SN), compact braided hoses (1SNK, 2SNK, 1SC, 2SC), textile hoses (2TE, 3TE), multi-spiral hoses (4SP, 4SH and isobaric hose types.

How does STAUFF ensure the quality of the connectors?

Before Ecovos was launched on the market, the hose fittings underwent extensive internal and external testing. The internal validation tests for all our hose connectors are carried out in our state-of-the-art testing facilities. Independent classification societies confirm the quality of our products. Our internal processes then ensure the consistently high quality of the fittings.

What are the advantages of using the STAUFF zinc/nickel surface?

The zinc/nickel surface ensures maximum durability and resistance, minimises assembly work (no lubrication required) and contributes to environmental protection by saving on lubricants.

Is there a stainless steel version?

Yes, we also offer our fittings in stainless steel as an option. With this variant, the Ecovos series becomes the Evocos VA product.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog