Table of contents

- Why safety is crucial with hydrogen

- Background: Hydrogen as an energy carrier

- Safety requirements for pipe clamps in hydrogen systems

- PA-EX: The special material for hydrogen systems

- Advantages of PA-EX in hydrogen applications

- Typical areas of application

- Installation and system consideration

- PA-EX as part of a comprehensive safety concept

- Conclusion: Safe and future-proof with PA-EX

- FAQs

Why safety is crucial for hydrogen

Hydrogen is considered a key raw material in the energy transition. At the same time, its use places the highest demands on safety technology: hydrogen is extremely flammable, and even the smallest sparks or electrostatic discharges can trigger serious explosions.

A holistic concept for explosion protection is therefore required in pipework systems, petrol stations, electrolysers or storage facilities. Seemingly simple components such as pipe clamps often play an underestimated role here: Not only must they be mechanically reliable, they must also be able to safely dissipate electrostatic charges.

Background: Hydrogen as an energy source

With the global ramp-up of the hydrogen economy, the need for safe and reliable plant technology is also increasing in a wide variety of areas:

Electrolysis plants for the production of green hydrogen

Storage systems and pipelines

Hydrogen refuelling stations and distribution infrastructure

Industrial plants, e.g. steel or chemical production

All these applications are located in potentially explosive atmospheres (ATEX zones). Therefore, all components used must be selected and planned according to strict standards in order to safely exclude ignition sources.

Safety requirements for pipe clamps in hydrogen systems

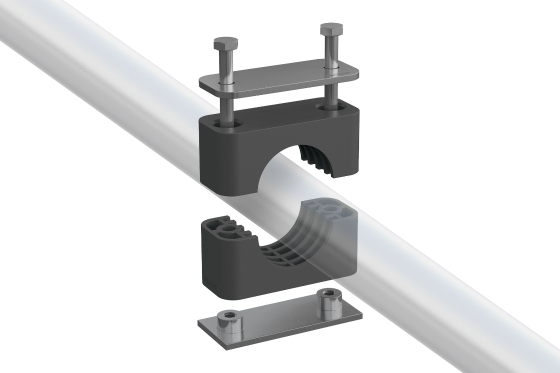

Pipe clamps are often underestimated - but they have an important safety function:

Prevent electrostatic charging: Pipes and system components can become electrostatically charged. Clamps must therefore be conductive.

Ensure systemic discharge capability: You must ensure that the pipework is connected to the potential equalisation.

offer corrosion resistance: Contact corrosion must not occur, especially with stainless steel pipes.

fulfil standard conformity: The relevant standards such as IEC 60079-0 or IEC 60079-32-2 specify strict limit values for leakage resistances.

PA-EX: The special material for hydrogen systems

PA-EX is a specially developed polyamide special material for EX applications:

Targeted electrical conductivity: leakage resistance < 1 Ω

Surface resistance < 10³ Ω according to IEC 61340-5-1

No independent charging possible according to IEC 60079-0

TÜV-tested quality, tested for conductivity under real operating conditions

This special material therefore fulfils all requirements for electrostatic safety in potentially explosive atmospheres - even in highly sensitive hydrogen applications.

Advantages of PA-EX in hydrogen applications

PA-EX pipe clamps offer decisive advantages especially for hydrogen systems:

Avoidance of electrostatic ignition sources: Prevents dangerous sparking.

No contact corrosion: Unlike aluminium clamps on stainless steel pipes, PA-EX does not lead to galvanic corrosion.

Tested safety: TÜV certification and IEC-compliant test procedures.

High flexibility: Available in many sizes, individually configurable.

Long-term investment security: compliance with international standards, including for future projects.

More information on PA-EX

For more details on the properties and general functionality of PA-EX clamps, we recommend the following:

The blog post on PA-EX Our materials page The data sheet on PA-EX

Typical areas of application

PA-EX pipe clamps are already being used successfully in the following hydrogen applications:

Electrolysis plants for the production of green hydrogen

Hydrogen refuelling stations

Storage and distribution systems (e.g. pipelines)

Compressor and compressor stations

Industrial plants with hydrogen pipework

Research facilities and pilot plants

Installation and system assessment

The best clamp alone does not guarantee safety - professional installation is crucial:

Only use unpainted stainless steel parts in the earthing path

Keep contact surfaces bright

Check the entire system for conductivity

Implement earthing concepts in accordance with IEC 60079-14

The responsibility for the discharge capability lies with the operator or system planner. PA-EX clamps are designed to fulfil these requirements in accordance with the standard and make planning easier.

PA-EX as part of a comprehensive safety concept

PA-EX clamps are an important component in explosion protection, but are no substitute for comprehensive planning.

Always integrate them into an ATEX-compliant overall concept

Combine earthing rails, potential equalisation, EX-certified components

Professional installation by trained electricians

Acceptance by qualified experts or EX officers

Regularly check and ensure the discharge capability during operation

Conclusion: Safe and future-proof with PA-EX

The hydrogen industry places the highest demands on plant safety - especially explosion protection. With PA-EX pipe clamps, electrostatic hazards can be reliably minimised and ATEX requirements safely met.

The result: greater safety, longer service life, less corrosion - and therefore an important contribution to the safe and sustainable ramp-up of the hydrogen infrastructure.

For detailed technical information, data sheets or personalised advice, please contact us.

FAQs

What exactly is PA-EX?

Does PA-EX fulfil ATEX requirements?

Yes - PA-EX clamps fulfil all conductivity requirements in accordance with IEC 60079-0 and IEC 60079-32-2 and are TÜV-tested.

Can I also use PA-EX clamps in other EX zones?

Absolutely - they are suitable for all EX zones in which electrostatic charging must be avoided, not just for hydrogen systems.

What do I need to consider during installation?

The conductivity depends on the overall system. There must be unpainted, conductive connection points and the installation must be carried out in such a way that continuous earthing is guaranteed.

Is there any further information on PA-EX?

a! Further technical details, background information and applications can be found in our first PA-EX article as well as on our page on clamp materials and in the corresponding data sheet.

Newsletter registration

Register now and don't miss any new articles!