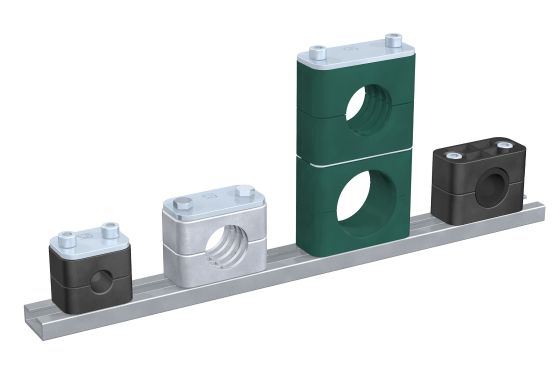

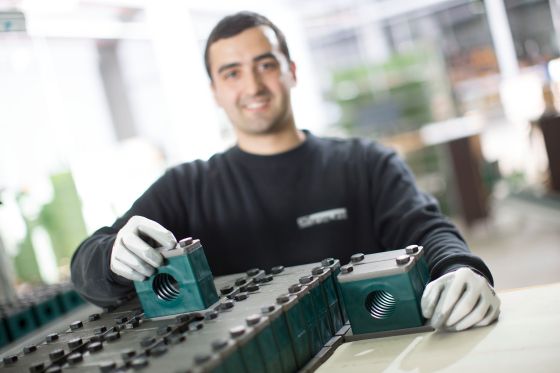

The requirements placed on cable systems are as varied as the industries in which they are used. As an experienced partner to industry, STAUFF has always made it its mission to develop solutions that go far beyond the standard.

Our clamps ensure secure, durable and efficient fastening of cables worldwide - adapted to a wide range of conditions.

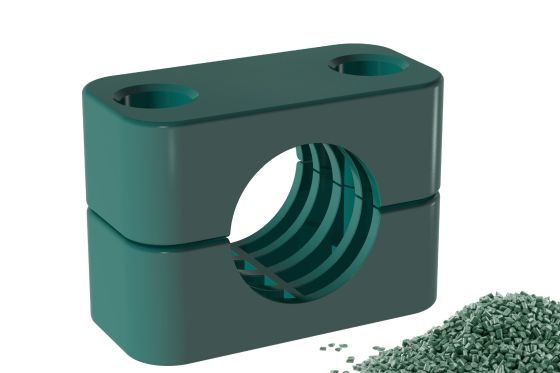

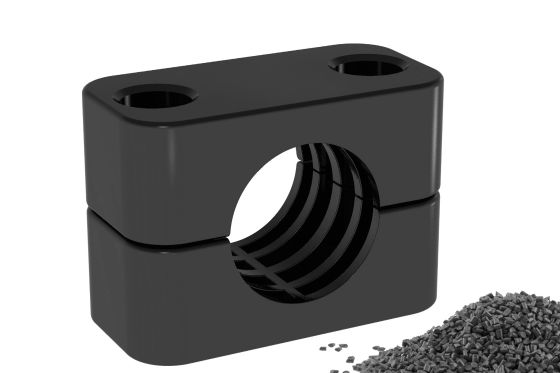

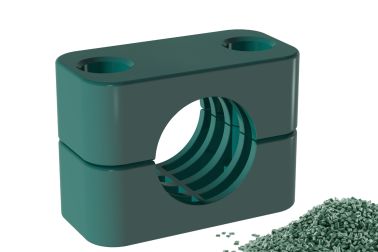

A milestone in our development was the introduction of polypropylene (PP) as the standard material for our clamp bodies. With this step, we have set standards in terms of functionality, cost-effectiveness and reliability. But at STAUFF, innovation does not end with the standard: in close co-operation with our customers, we have developed a comprehensive portfolio of materials that specifically addresses special requirements.

Whether for extreme temperatures, aggressive media or high mechanical loads - every material in our range is optimised for the specific benefit to our customers. The constant further development of new materials, such as the latest sustainable material PP-ECO made from recycled polypropylene, emphasises our commitment to forward-looking, resource-saving solutions.

Thanks to this consistent customer focus, we now offer one of the widest ranges of materials on the market - and the ideal clamp for almost every application.