What is an alternating valve?

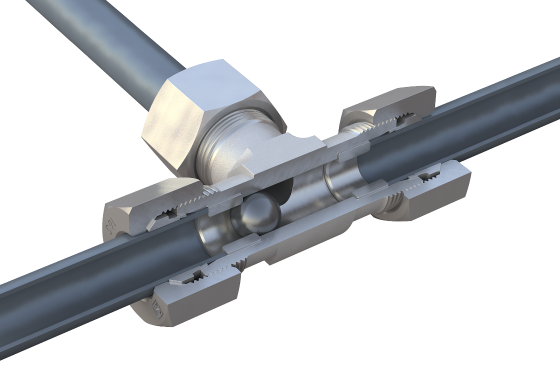

alternating valves are special hydraulic valves that act as automatic diverter valves. They allow the pressure to be switched from one connection to another - the non-pressurised connection is securely closed by a movable steel ball in the valve body. This mode of operation ensures reliable control and distribution of hydraulic fluids in complex systems.

How do these valves work?

The centrepiece of an alternating valve is a spherical sealing component located inside the valve body. As soon as pressure is applied to one port, the ball is mechanically pressed into a position that tightly seals the other port. This automatically diverts the pressure flow to the pressurised connection and protects the free connection against backflow. This simple and robust mode of operation enables fast and safe changeover without external control.

Types and standards of alternating valves

STAUFF offers alternating valves from the FI-WV series in two versions:

- Light series

- Heavy-duty series

Both are manufactured in accordance with ISO 8434-1 and DIN 2353 standards. In the light series, they are designed for nominal pressures up to 250 bar, and in the heavy-duty series even up to 630 bar. The valves are equipped with tube fittings and cutting ring fittings from the STAUFF Connect series made of steel with a 24° internal cone, which ensures high tightness and easy installation.

Areas of application for alternating valves

Alternating valves are used in numerous hydraulic applications where two pressure lines need to be automatically and safely separated or switched over. Typical areas of application are

Hydraulic systems in mechanical and plant engineering

Control of power transmissions

Securing circuits against backflow

Automated switching between two pressure sources

A particularly common area of application is on test benches - for example in quality assurance or development. Here, alternating valves enable automatic switching between different pressure levels or pumps without the need for manual intervention. They ensure that only one pressure source acts on the test system at a time and at the same time prevent unwanted backflow. alternating valves offer a compact and reliable solution, particularly for leakage or function tests, for example on cylinders, valves or pumps - both for the control system and for the safety of the test setups.

Advantages of STAUFF valves

Our retractable valves have a number of advantages. We don't want to withhold these from you. Our product managers will be happy to provide you with further information at any time. Here are the significant advantages at a glance:

Reliable tightness: Metal-sealed ball guarantees no leaks.

Robust construction: High-quality steel and precise workmanship ensure a long service life.

Standardised: Complies with ISO 8434-1 and DIN 2353 - optimum compatibility.

Versatility: Available in light and heavy-duty versions for different requirements.

Simple installation: STAUFF Connect fittings ensure quick and secure installation.

Selection criteria

The following factors should be taken into account when selecting an alternating valve:

- Pressure range: Suitable for the system pressure, with STAUFF up to 630 bar.

- Connection type: Compatible with pipe fittings in the system.

- Material: Steel for robust applications, special coatings for corrosion protection if necessary.

- Series: Light or heavy, depending on the operating conditions.

- Standards: Important for compliance with technical standards.

Alternating valves in the STAUFF online shop

In the STAUFF online shop you will find a wide selection of high-quality alternating valves from the FI-WV series. Whether light or heavy-duty - all products impress with their tested quality, simple installation and high reliability. Benefit from fast delivery times and expert advice.

FAQs

What is the main purpose of an alternating valve?

What pressure ranges do STAUFF valves cover?

The valves are designed for nominal pressures up to 630 bar.

What does the distinction between the light and heavy series mean?

It describes the design in terms of load capacity and area of application - the heavy-duty series is more robust and suitable for more demanding applications.

What connection types are available?

STAUFF alternating valves are equipped with tube fittings and cutting ring fittings from the STAUFF Connect series with 24° internal cone.

Where are alternating valves mainly used?

Mainly in hydraulic control systems, mechanical engineering and industrial applications where automatic pressure changeover is required.

Newsletter registration

Register now and don't miss any new articles!