The STAUFF Kanban system offers an individually designed and thus precisely tailored procurement solution for specific customer requirements with maximum process, quality and supply security.

An optimal service solution for automatic replenishment is implemented, tailored to the type and range of articles, the working environment of the users/consumers and their needs. The focus is on maximum availability of the components in the right quantity, at the right place and at the right time.

A rolling container system provides STAUFF components "just-in-time" directly at the assembly site. In addition, it offers a high adjustment capability in the event of changes in requirements with maximum delivery and supply security and reduces customer-side inventories with low commitment of capital.

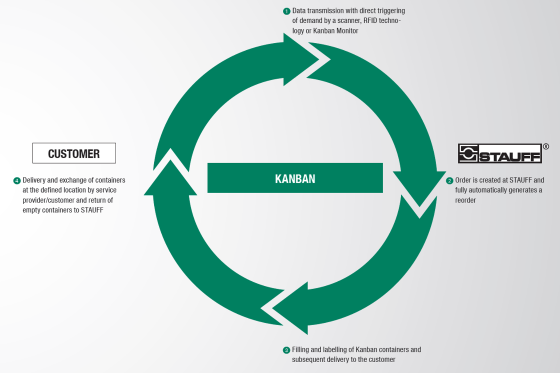

Basic Principle of the STAUFF Kanban System

General Conditions of the STAUFF Kanban System

Equipment required

The required equipment, such as shelves, containers, scanners or RFID technology, labels etc. is provided by STAUFF. STAUFF provides its own containers in two different sizes. The containers are subject to a continuous cleaning process.

Upon agreement, the customer's existing equipment can also be integrated into the process.

Filling quantities and control circuits

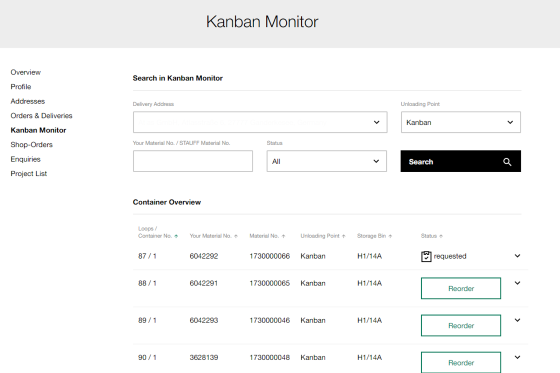

Fixed fill quantities can be individually agreed and stored via control circuits. The demand is triggered either by scanning the barcodes or by automatically reading the RFID tags of empty containers with direct data transmission to STAUFF, which triggers the reordering. All control loops can be viewed and ordered in the Kanban monitor on the STAUFF digital platform.

On-time delivery

On-schedule delivery of the filled and pick-up of the empty Kanban containers takes place at the agreed transfer point or directly at the assembly line.

Labelling with the STAUFF Kanban System

All containers are provided with interchangeable labels and thus offer all relevant information at a glance:

- Customer logo / STAUFF logo

- Recipient of goods

- Print date

- Customer article number and customer designation

- Container content

- Container type and shelf location

- Barcode

In addition, there is a shelf label at each storage location. This ensures easy allocation of the container to the correct shelf location. When using RFID technology, an RFID tag is also attached to the container.

Advantages of the STAUFF Kanban system for the customer

- Maximum availability of the required components in production / assembly

- Selection from over 50,000 standard hydraulic and fluid power components from one manufacturer

- Reduced process costs in the areas of purchasing, logistics and administration

- Reduced capital commitment

- Increased flexibility within your value chain

- Precise control of the flow of goods

- Punctual delivery through the automated STAUFF logistics centre

- Personal advice from employees with industry know-how

- Transparency in every step of the replenishment process through the Kanban Monitor